Activated carbon is used by numerous industries for various applications including filtration (e.g. removing color from syrups in the sugar or food processing industries, purifying drinks, treating drinking or industrial water or treating combustion gas) because of its excellent absorption properties.

As it is used, activated carbon loses its effectiveness and is eventually saturated. It is therefore necessary to regenerate it using steam so that it can be re-used.

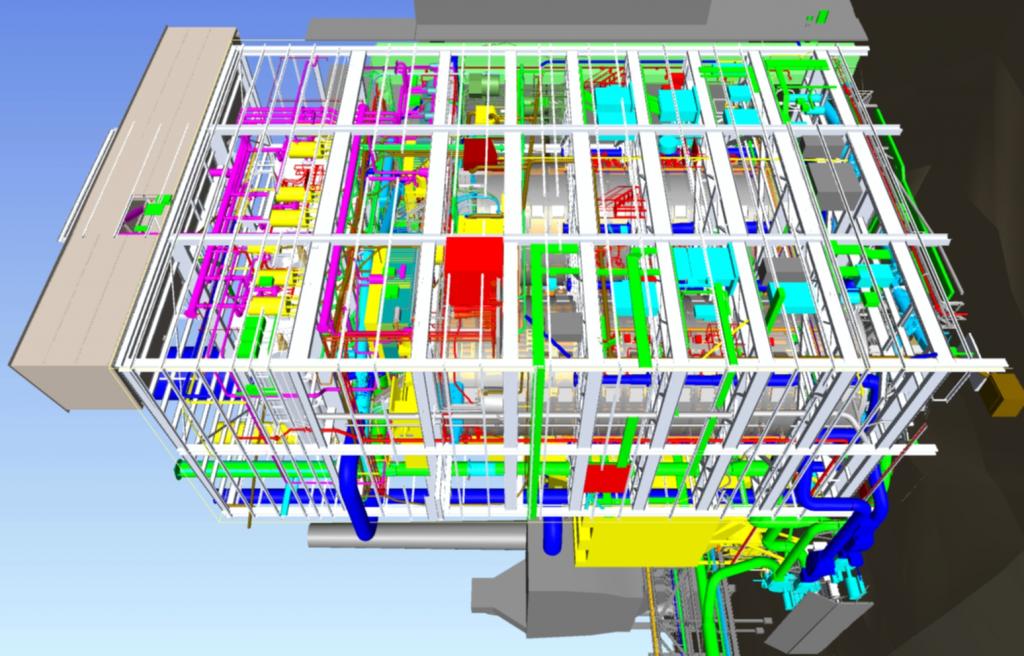

Thanks to the Multiple hearth furnace (MHF) developed by The Nesa Solution®, the ‘contaminated’ carbon will be regenerated in a controlled atmosphere and according to a treatment temperature profile specific to the organic pollutants which it contains. Following regeneration, the activated carbon regains its initial structure and absorbing characteristics.