New Twin Acid Regeneration Plant for BAOWU: an innovative & environmentally friendly concept combined with smart technologies

May 21st 2021

The twin ARP ordered by BAOWU, one of the Chinese steel giant’s subsidiaries, comes with an innovative & environmentally friendly concept, combined with smart technologies.

This is the 3rd Twin Acid Regeneration Plant (ARP) that the BAOWU Group recently ordered from John Cockerill. The steel giant knows that an acid regeneration plant perfectly matched with its pickling processing lines, not only guarantees the efficient management of consumable process chemicals and maximizes operating efficiency, but also minimizes the environmental impact of its plants.

While with its inauguration this year, BAOWU’s Twin Fluidized Bed (FB) ARP in Shanghai will be the world’s largest and most environmentally friendly acid regeneration installation, this latest order has been placed by WISCO (Wuhan Iron & Steel Company), a member of the CHINA BAOWU Steel Group.

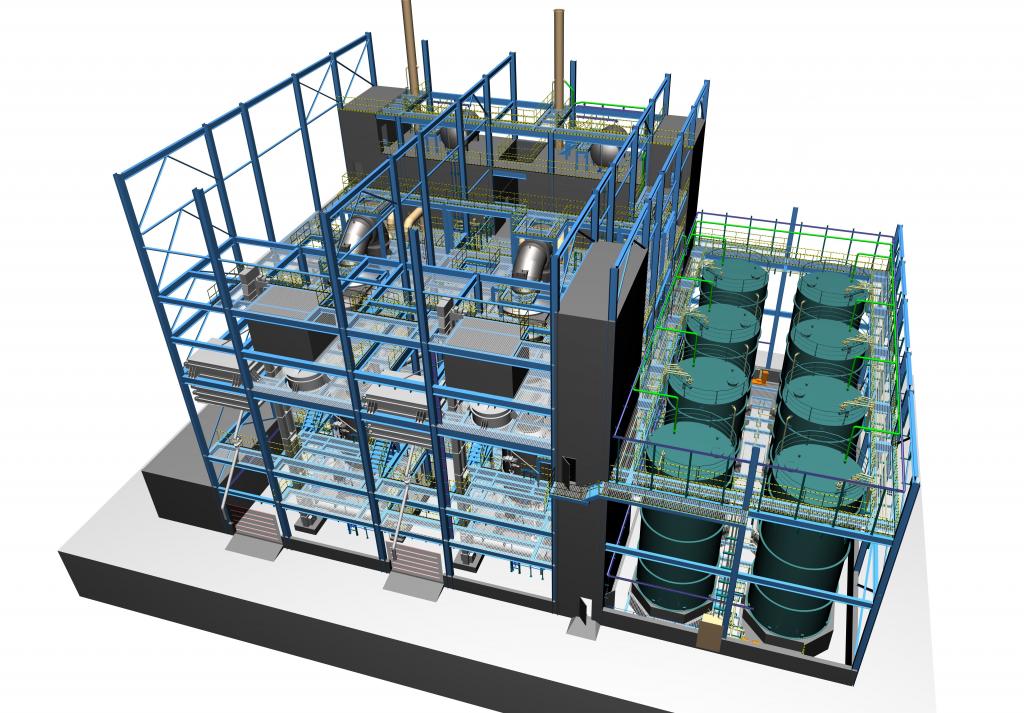

The new Twin Acid Regeneration Plant is made up of two acid regeneration plants with a capacity of 7500L/h each and a dedicated tank farm. The plant features the full spectrum of the very latest process technologies and is providing emission values for both HCl & dust that are far under the legal value of 10mg/Nm³. Another distinguishing feature is the use of coke oven gas as an energy source, that is to minimize flare-offs and natural gas purchases.

Today John Cockerill’s state of the art acid regeneration plants are characterized by their innovative & environmentally friendly concept, particularly in terms of emissions and waste energy recovery, combined with smart and Industry 4.0 technologies. The recent orders coming both from Europe and China are compelling testimonies of how relevant these developments are in the face of ever more stringent environmental policies.