As a leader in the acid regeneration industry, John Cockerill offers modular design options guaranteeing its clients the best possible solution to meet their requirements and suit their applications and an almost 100% acid recovery rate.

Carbon and silicon steel

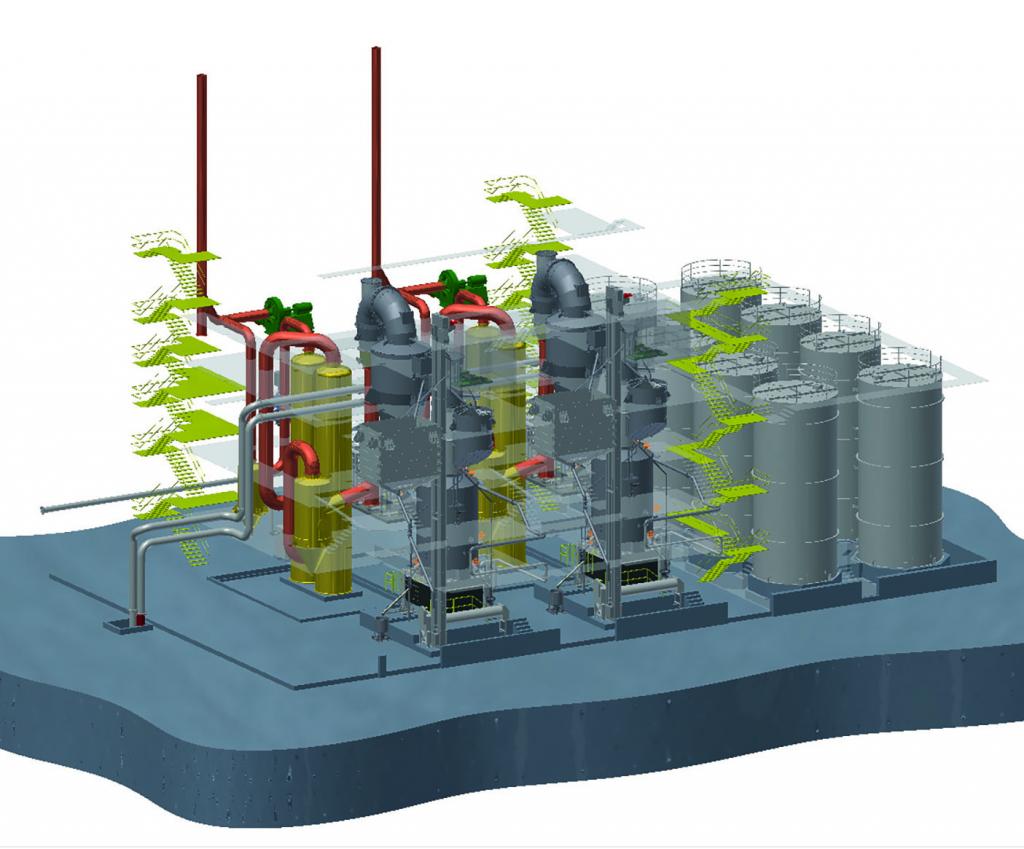

John Cockerill offers both proven pyrohydrolysis processes – fluidised bed and spray roaster- and it is often difficult to choose between the two. We can help you choose the best option depending on your particular needs and requirements, notably providing you with access to the quick-change spray nozzle, our new venturi design requiring no maintenance, or the most successful plant control system there is, allowing you to manage your entire facility from a single control station.

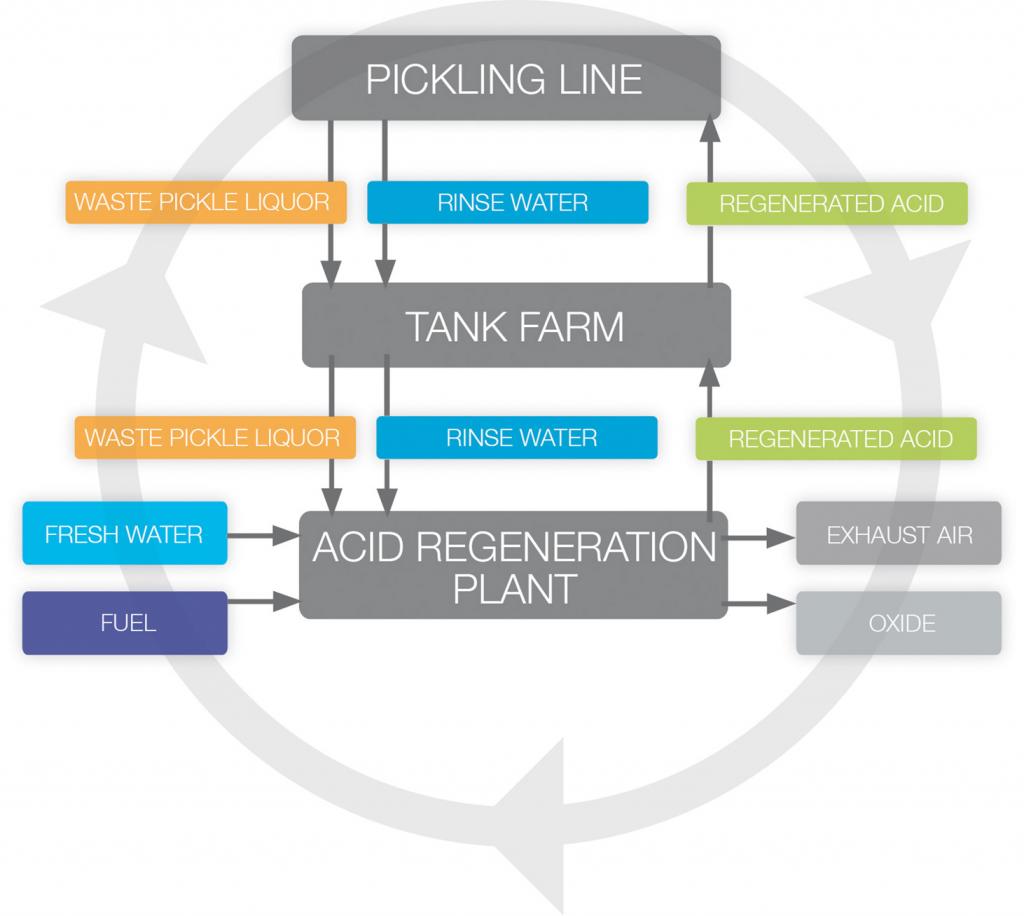

With regards to complete hydrochloric acid (HCl) regeneration, the spent acids produced during the pickling process are concentrated by heating and mass transfer in the venturi before being injected into the spray roaster device or the fluidised bed reactor, where it reacts with the O2 and H2O to form iron oxide and hydrogen chloride.

The hydrochloric acid contained in the gas produced by the reactor is then fed into a system in which the rinsing water from the picking line is circulated against the flow. This water absorbs the gaseous acid so that virtually 100% of the effluent is converted back into liquid acid, which can then be reused in the pickling baths. The remaining gas is treated in several stages before being released into the atmosphere.

The range

For carbon and silicon steels

- Fluidised bed acid regeneration facility

- Spray roaster acid regeneration facility

Main benefits

- Environmental protection through the recovery of hazardous chemicals;

- Almost emission-free operation;

- Recovery of costs through the sale of oxide as a high-quality co-product;

- The highest processing speed on the market;

- Optimised pickling owing to the consistency of operational parameters;

- Independence from acid suppliers;

- Rapid return on investment;

- Compliance with current and future legal requirements regarding emissions;

- Low maintenance costs;

- Proven design;

- Can be adapted to any type of pickling line.