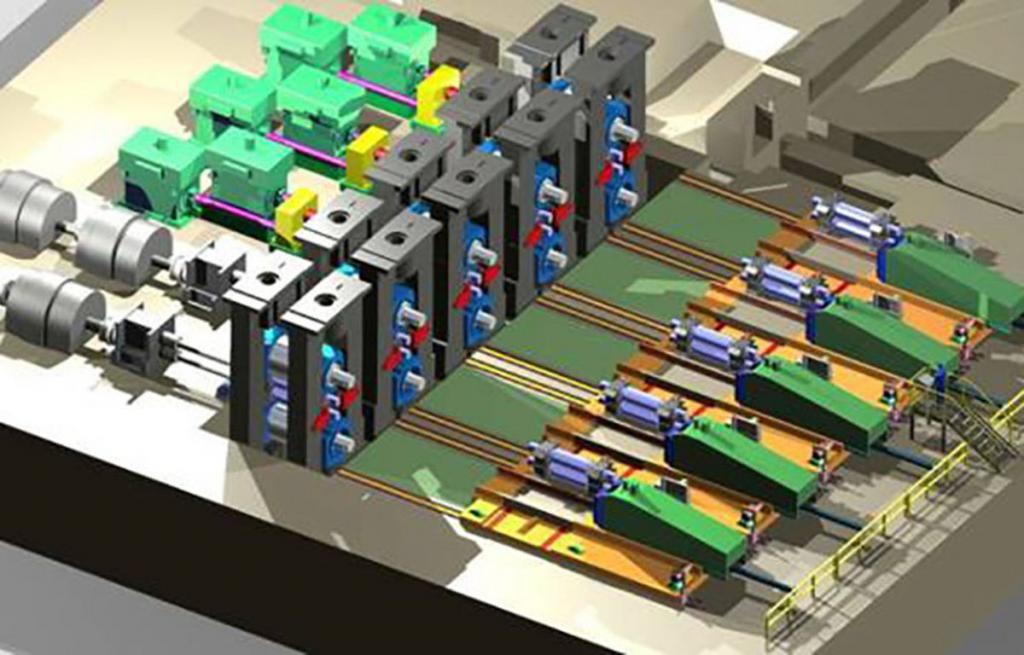

John Cockerill has amassed over 30 years’ experience in the design and production of rolling mills. Its latest-generation cold rolling mills are designed to be extremely efficient and flexible and to consistently meet the specific needs of its customers, reducing downtime, monitoring tension and tracking and ensuring optimal product thickness and evenness. This value is even further enhanced thanks to tried and tested equipment such as shearing systems, tension levelling, descaling facilities, mandrels and winders, all of which play a key role in the modernisation and installation of new rolling mills and new combined pickling lines and tandem cold mills (PLTCM).

John Cockerill has trained a substantial team of experts who create solutions to demands for increasingly high production capacities and improved product quality by designing new equipment and upgrading existing hot and cold rolling mills. These experts also incorporate the latest developments from the automotive and tinplate industries, along with appropriate process models and automation and control options.

John Cockerill designs high-capacity reversible quarto and sexto cold rolling mills that offer a high degree of flexibility across all metal rolling applications. These rolling mills can incorporate one or two cages and can be used to roll a wide range of products, including steels containing low, medium and high levels of carbon, copper, brass and various other alloys of any width, operating at a speed that meets the needs of even the largest of steel complexes. Programming models are provided with the equipment.

John Cockerill also offers a range of wet and dry skinpass systems that can be designed to be used alone or in conjunction with continuous annealing or galvanising lines. Skinpass systems can process a wide range of widths, ensuring accuracy of output thickness and achieving very high speeds, thus ensuring a high level of productivity and excellent cost-effectiveness.

The range

- Rolling mills:

- Cold rolling mills (discontinuous and continuous)

- Pickling lines and tandem cold mills (PLTCM)

- Reversible cold rolling mills (quarto and sexto, single-cage and dual-cage)

- Skinpass rolling mills that can be operated wet or dry and either alone or incorporated into continuous annealing or galvanising lines

- Upgrading and special equipment for hot and cold rolling mills

Key benefits

- Suitable for a wide range of strip widths and thicknesses;

- Suitable for a wide range of products (steels containing low, medium and high levels of carbon, silicone steels, copper, brass and various other alloys);

- Reliable equipment that reduces downtime;

- Precision traction control;

- Optimal strip thickness and evenness;

- Sufficient speed for even the highest of volumes.