Towards carbon neutrality with the COMPASsCO2 solar project

January 21st 2021

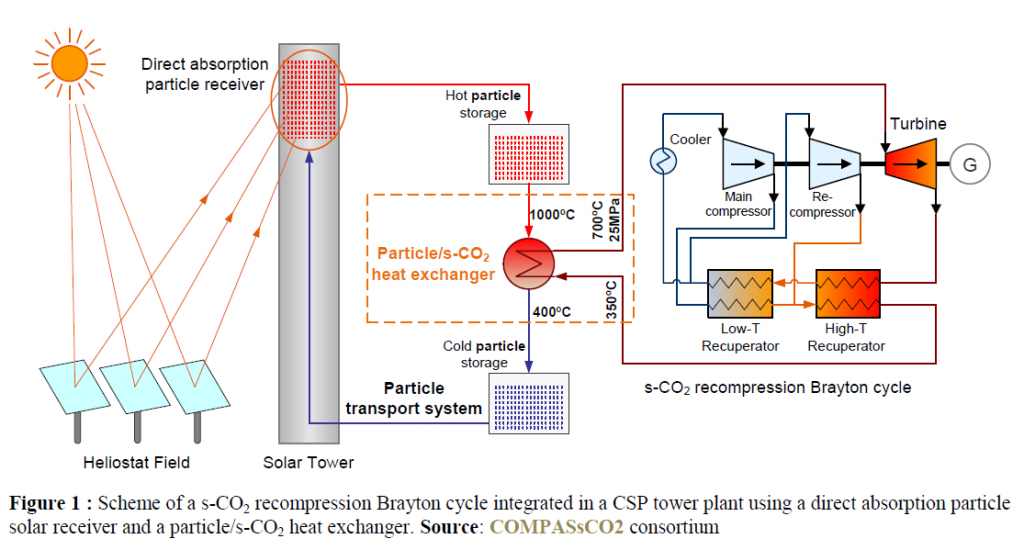

The COMPASsCO2 project gathers different companies, research centers and universities in Europe to investigate a new type of Central Solar Power (CSP) plant with tower. This research and development project aims to achieve the challenges of decarbonization by 2050 as defined by the European Union.

The outputs of the COMPASsCO2 (Components’ and Materials’ Performance for Advanced Solar Supercritical CO2 Powerplants) investigations will pave the way to the use of supercritical CO2 (s-CO2) in CSP plants as a working fluid in a thermo-dynamic cycle for electricity production.

Charly Rensonnet, Development Engineer for John Cockerill Solar & Thermal Storage : “The s-CO2 is a carbon dioxide fluid phase obtained by maintaining it above its critical temperature and pressure which are respectively 31°C and 74 bars. In that state, the carbon dioxide has both liquid and gaseous features: a high density like liquids and a low viscosity like gases which makes it an ideal candidate for thermal energy transport.”

The thermodynamics cycle will be supplied in thermal energy thanks to a solar tower using solid particles in spite of the common molten salts. The solid particles will be heated up with concentrated solar rays in a receiver located at the top of the tower.

The most valuable asset of replacing liquid salts with solid particles is the ability to heat them up to 1000°C, whereas the salts are limited at 565°C. “This results in an increase of the plant global efficiency and an increase of the solar energy exploited. The missing link between the solar tower and the s-CO2 cycle is a heat exchanger transferring thermal energy from the particles to the s-CO2.” The consortium will therefore develop such a heat exchanger while keeping the spotlight on the development of relevant mate-rials that can withstand very high temperatures and abrasion (because of the moving particles).

Once all technical constraints are quantified and taken into account (highest reached temperature, abrasion, etc) the best metal alloys will be defined and used for the heat exchanger manufacturing. “John Cockerill is responsible of de-signing a downscaled heat exchanger that will be tested on an existing s-CO2 loop from one of the consortium’s partners”, says Charly Rensonnet.

The particles type will be defined as well during the project to fit the technical constraints but their size will be somewhere between 0.5 and 2 mm. Concerning the heat exchanger concept, it consists in different row of tubes through which the s-CO2 flows and on which the hot particles fall.

As John Cockerill’s involvement in this R&D project shows, innovation is key. COMPASsCO2 shows the importance of our technologies to facilitate both decarbonization and access to renewable energies.