John Cockerill develops a 100% European hydrogen chain to decarbonise industry and mobility

October 27th 2021

With hydrogen, John Cockerill is committed to drastically reducing CO2 emissions from industry and transport. To achieve this, the Group is currently participating in the deployment of hydrogen ecosystems, within which it is positioned as a designer and supplier of large-capacity production and distribution solutions and, further upstream still, as a designer and operator of electrolyser Gigafactories, production plants dedicated to these technologies.

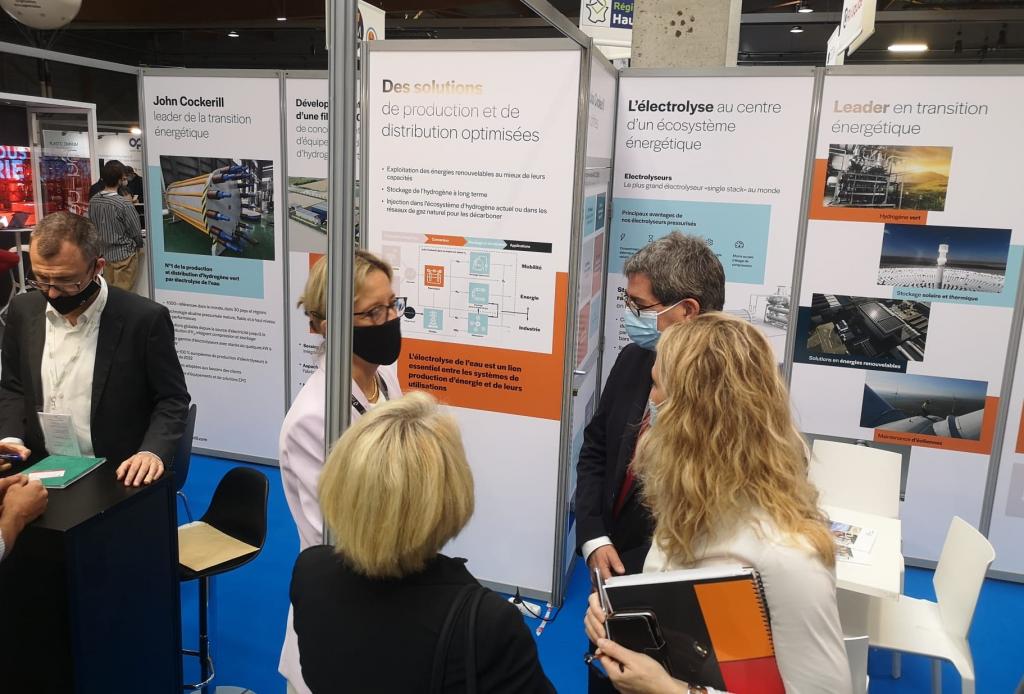

Meet our experts at Hyvolution 2021.

Steel production alone emits 2.4 billion tonnes of CO2 into the atmosphere every year from blast furnaces. The same applies to lime, petrochemicals and many other industries. The transport sector is the second largest source of greenhouse gases in the world.

Faced with this observation, John Cockerill has chosen to put its two centuries of innovation and expertise at the service of the decarbonisation of these sectors. In particular, drawing on its know-how in electrolysis, it has been supplying electrolysers to produce hydrogen from water for the past five years. This hydrogen, provided that it is produced from decarbonised energy, is increasingly becoming the “zero emission fuel of the future” both for industrial tools of all kinds and for mobility (trains, trucks, buses, boats and other means of transport). The hydrogen sector therefore has enormous potential for reducing CO2 emissions, but also for creating jobs and value, provided a number of political, economic, industrial and technological challenges are met.

Gigafactory in Alsace

From an industrial point of view, John Cockerill is currently the leader in large-capacity electrolysers (6+MW), with a 20% share of the world market in 2020. In line with France’s ambition to play a leading role in the development of the hydrogen industry, John Cockerill is developing in Alsace one of the two gigafactories announced by Emmanuel Macron in his speech of 12 October 2021 on France’s Ambition 2030. The first 100% European electrolysers should come on stream at the beginning of 2023 and gradually reach a production capacity of one Gigawatt.

Research & Development

This industrial prowess is accompanied by a strength of innovation that only a group with multiple technologies like John Cockerill can offer. On the agenda of its research and development teams is the regular increase in the capacity of John Cockerill electrolysers, which are already the largest on the world market (6+MW). Another technological challenge to improve the attractiveness of the sector is to reduce not only the production cost of electrolysers but also, and above all, to improve their energy performance and therefore their electricity consumption. Behind its own resources, John Cockerill is pulling in its wake a whole ecosystem of French start-ups and SMEs active in hydrogen, and is developing partnerships with research centres. The latest example: through the IRT- M2P in Metz, John Cockerill will provide this ecosystem with a full-scale demonstrator where each innovation can be tested, with the aim of accelerating the establishment of the hydrogen sector in France.

In addition to work specifically focused on hydrogen production and distribution, John Cockerill’s engineering teams are also preparing to adapt industrial processes to the use of hydrogen as a fuel. To stay with the steel comparison, the technology for producing hydrogen-based steel differs greatly from that for steel produced from cast iron and coal.

Discover two application examples: hydrogen to decarbonise the lime industry with the Columbus project and hydrogen to decarbonise airport mobility with the HaYrport project.