A high-speed Continuous Color Coating Line (CCL) for a leading steelmaker in the USA

November 28th 2022

After the order of a Continuous Galvanizing Line (CGL) at the end of last year, one of North America’s biggest steelmakers has reconfirmed its confidence in John Cockerill’s technologies and equipment by ordering another high-performance processing line.

The new highly versatile Color Coating Line (CCL) to be supplied to a leading steelmaker in the USA, is to produce an almost infinite variety of top-quality products for the home appliance, trailer and door-&-gate industry, as well as for multistory and industrial construction.

One of the fastest Color Coating Lines ever built

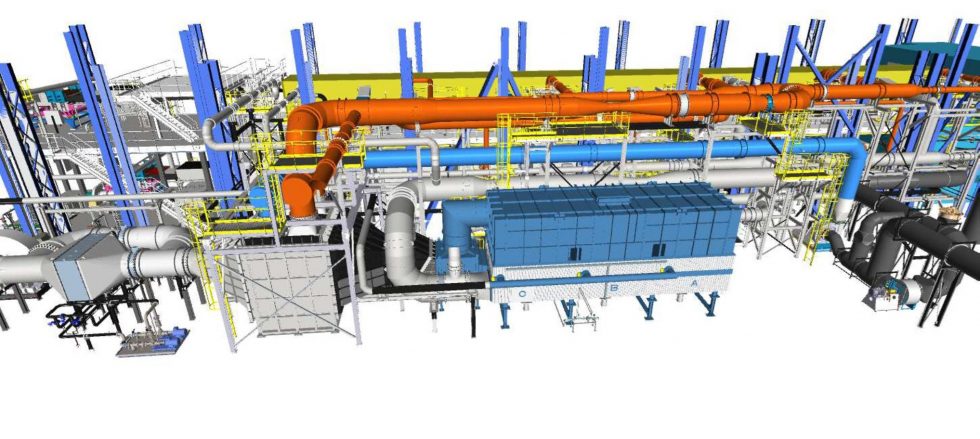

Catering for a massively growing Color Coated Steel Market, the new line to be supplied by John Cockerill, is aiming at cost-effectiveness, functionality, ease of processing and low energy consumption, is to provide the most accurate and highest-quality surface coatings. The wide range of coatings includes zinc & iron phosphate pre-treatment and embossed coatings.

With a production speed of up to 210m/min, it is one of the fastest color coating lines ever built. It is to process strips with a width of 914mm up to 1550mm and thicknesses ranging from 0.25mm to 1.3mm. With an annual capacity of 376,000t, the line processes ColdRolled, Galvanized, & Al/Zn steel strips.

Allow the client to produce responsibly

Important line features to help the client produce sustainably and effectively cater for this high-growth potential market, are the Catenary Heating Oven ensuring a complete curing of the paint coatings, the Regenerative Thermal Oxidizer (RTO) for the most effective solvent abatement, the laser welder for flexible and resistant coil joining, as well as the pre-degreasing and degreasing sections for the highest possible strip cleanliness.

For this new state-of-the-art processing line, John Cockerill is providing the comprehensive range of services from planning, design, manufacture to assembly and commissioning.