John Cockerill to equip the Pau (France) wastewater treatment plant with a nitrogen recovery solution and deodorization units

January 23rd 2023

John Cockerill Environment has been selected by SUEZ to equip the latest generation wastewater treatment plant of Pau-Lescar (France) with a nitrogen recovery solution and deodorization units.

Heading towards circular economy with the Pau Béarn Pyrénées urban community (31 municipalities, 160,000 inhabitants) which has decided to transform its wastewater treatment plant into a real “resource factory” that, in the long term, is to create 10 energy and resources from wastewater. A methanization unit coupled with a methanation stage will recover the sludge from the STEP and transform it into biomethane (CH4). The goal: to meet the challenges of the ecological transition and move towards decarbonization by 2040. An exceptional and avant-garde project using cutting-edge technologies!

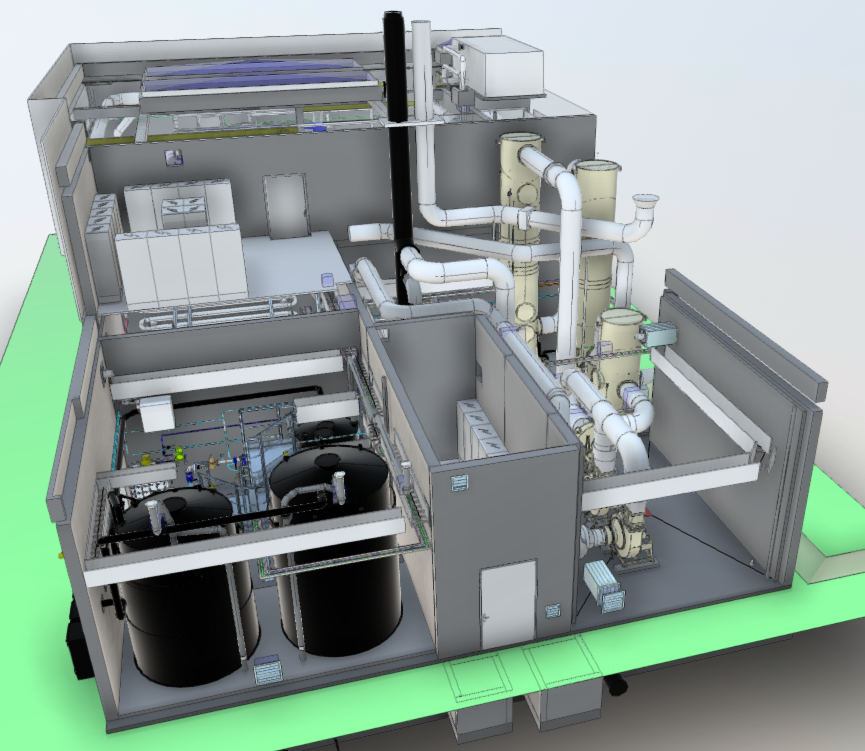

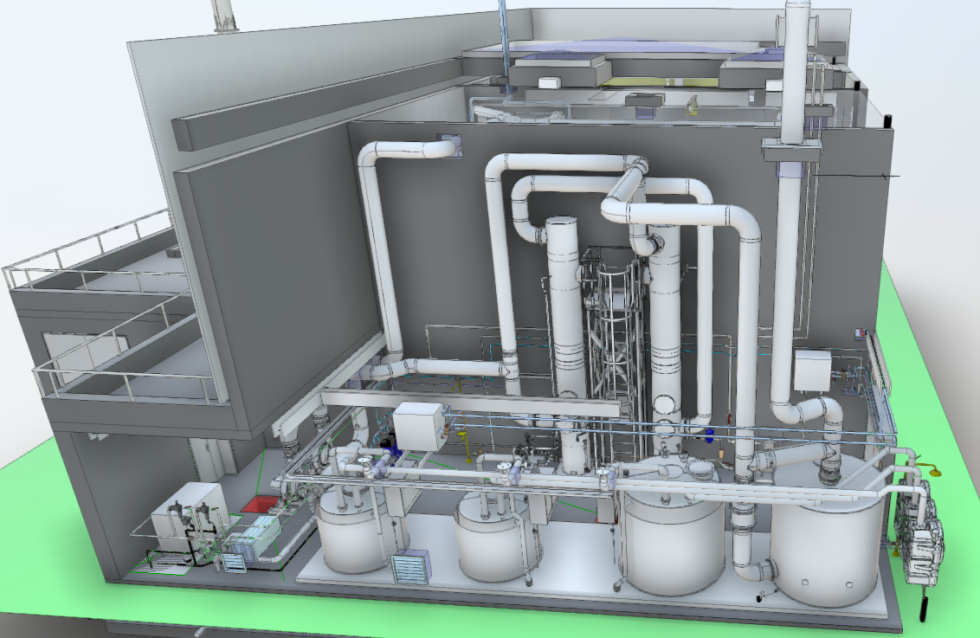

It is in this context that Europe Environnement, John Cockerill Environment’s French specialists in air and odor depollution, was chosen by SUEZ to equip the new positive energy wastewater depollution plant, with a nitrogen recovery unit to produce mineral fertilizer from liquid biogas residues. These are indeed containing a considerable amount of nitrogen, a compound that must be eliminated before the wastewater reaches the treatment plant. Nitrogen is thus extracted via a stripping unit using “green heat” recovered on site. A technology perfectly mastered by our experts. The obtained product is a solution of ammonium salts that can be used as a liquid agricultural fertilizer, very popular with local market gardeners. With the annual production of 320 m³ of ammonium sulphate, 570 ha of maize crops can be fertilized each year!

Additionally, John Cockerill Europe Environnement will also supply 2 odor treatment units:

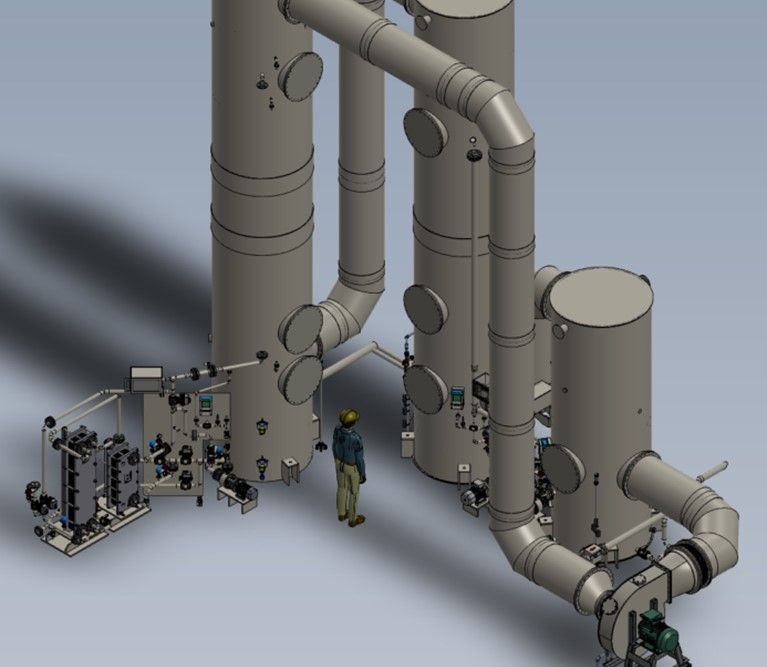

- A double-story activated carbon treatment unit with a capacity of 10,000 m3/h to treat odors emanating from the building dedicated to the thickening of the sludge.

- Dedicated to the ultra-dehydration by hydrothermal carbonization, the HTC (HydroThermal Carbonization) building’s deodorization is ensured via a physico-chemical gas washing and a finishing step using activated carbon with a capacity of 2,600 m3/h.

John Cockerill is proud of having been chosen to equip this pioneer wastewater treatment plant producing positive energy, with technologies at the cutting edge of innovation, allowing to adapt to the changes in our society.

As such, this industrial ecosystem addresses several of our society’s major current challenges: energy sovereignty and circular economy.