For AHSS, UHSS, and electrical steels, we deliver fully integrated Combi CAL–CGL lines, JVD® coating, E-Si® systems, and adaptive cooling with Blowstab®, IWAC®, and UDC®.

Performance advantages:

- High coating consistency

- Up to 10% zinc savings

- Lower energy use and CO₂ emissions

- Greater operational stability

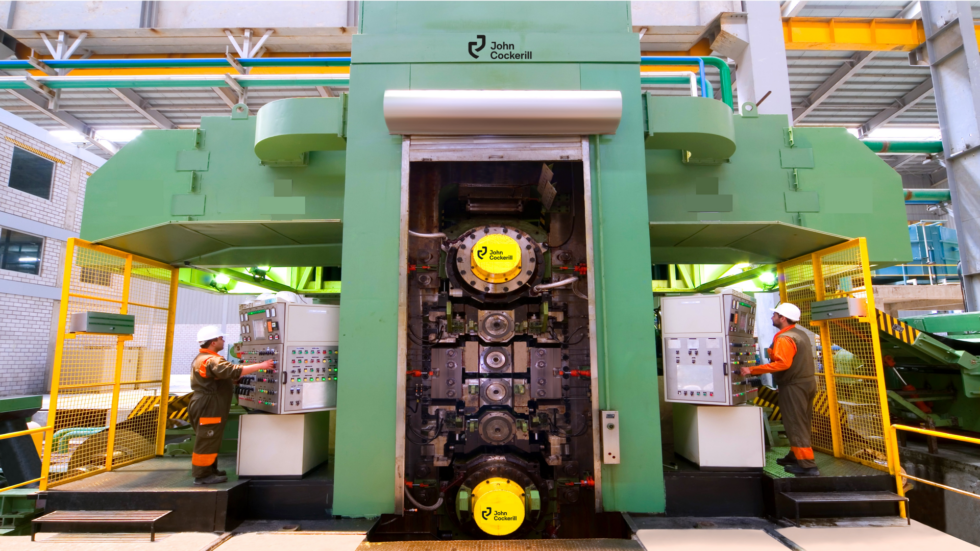

High-performance strip processing lines and equipment for all applications

John Cockerill responds to the challenges its clients face by providing them with solutions for treating the latest high-resistance steels (AHSS and UHSS), including DP (dual-phase), TRIP (transformation-induced plasticity), FB (ferrite-bainite), CP (complex phase) and TWIP (twin-induced plasticity).

Very high-resistance steels (AHSS and UHSS) are considered the best option for decreasing the weight of a vehicle. The steel industry is now in the process of preparing the third generation of this type of steel and John Cockerill is developing solutions to the technological challenges that they represent, which requires a certain amount of innovation with regards to automated cooling techniques. With this in mind, we have also developed a patented pre-oxidation chamber process that controls oxidation on the surface of the strip linked to the annealing of silicone steels and ensures good zinc adhesion. Combining the pre-oxidation and oxidation chambers makes it possible to control oxidation on both sides of the strip.

With regards to steel strip processing equipment, John Cockerill offers a comprehensive range of lines, furnaces and other equipment designed and manufactured to add maximum value. We design and deliver new facilities whilst at the same time upgrading and improving the quality and productivity of existing lines. Taking our clients’ needs as our starting point, we develop innovative combined line solutions, including, for example, combined continuous annealing and galvanising lines (Combi CGA-CGL) that guarantee a superior surface quality for very high-resistance automotive structural parts. Combined continuous galvanising and colour coating lines limit investment costs and working capital needs by reducing stock levels whilst at the same time eliminating the need to oil the galvanised strip or remove any grease before colour coating.

Our hot-dip galvanising lines mean that we are able to apply a wide range of coatings, including our latest offering, ALuSi.

Our cutting-edge strip processing lines incorporate all of our latest innovations, including a several-stage strip cleaning process, vertical furnaces (including the L-Top mathematical model and the energy-recovering Jet Cooling System), the soaking section and the Air Knife system, the APC Blowstab® cooling system, the online skinpass system and the tension levelling system, organic and chemical post-treatment procedures, side trimmers and exit shears.

The range

Strip processing lines

- Continuous annealing lines (CALs);

- Continuous hot-dip galvanising lines (CGLs) designed to apply various coatings, including the very latest AluSi coatings;

- Dual-product lines;

- Continuous electro-galvanising lines (EGLs);

- Electrolytic cleaning lines (ECLs);

- Flow lines;

- Colour coating lines (CCLs);

- Inspection/correction/tension levelling lines.

Process equipment

- Multi-stage cleaning section;

- Bath equipment (zinc pot and air knife system);

- Tension levelling/Skinpass rolling mill;

- Chemical and organic roller coaters;

- Shears / Side trimmers / Slitters.

Key benefits

Strip processing lines

- Reliability;

- High production outfit;

- Optimised processing sections (mechanical, thermal and chemical);

- High operational flexibility;

- Proven optimised availability;

- High and consistent product quality;

- Line design conducive to reducing maintenance costs (easy maintenance of equipment increases its availability).