Once Through Boilers offer a reduced carbon footprint, higher cycle efficiency, and enhanced operation flexibility

November 25th 2024

Enhancing cycle efficiency, reducing your environmental footprint, and lowering costs for your combined cycle power station, cogeneration plant? Opt for a Once Through Boiler!

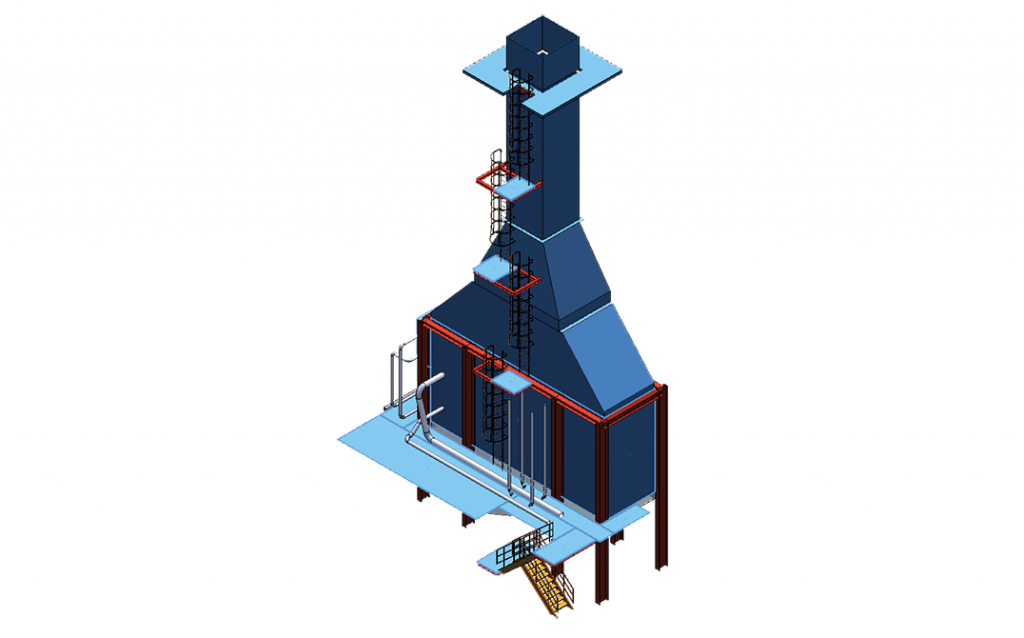

With their optimized vertical design, John Cockerill’s Once Through Boilers offer a reduced carbon footprint, higher cycle efficiency, and enhanced operation flexibility. With their dry running capability, our OTBs can be installed behind gas turbines from 15 to 100 MW. These vertical OTBs offer superior operational flexibility and are designed to unrestricted start-ups and shutdowns of gas turbines without use of by-pass stack thanks to dry run capability.

In response to today’s stringent needs, John Cockerill’s unique modular design maximizes the adaptability of its boilers to a wide range of industrial applications. Our modular design offers the highest level of prefabrication, which allows a significant reduction of the on-site construction time and therefore meets the tightest deadlines.

Moreover, with their compact footprint, even when equipped with a Selective Catalytic Reduction and a CO catalyst, John Cockerill’s Once Through Boilers are designed to offer better accessibility and reduced maintenance costs.

John Cockerill is Original Equipment Manufacturer of HRSGs and Technology Owner, who masters this technology of vertical Once Through Boilers for either small gas turbines with dry running mode, or for the largest gas turbines to enhance plant heat rate at higher high pressure above 175 bar. Our latest reference for this kind of boilers is in construction in the power station of Mintia, Romania, where 2 John Cockerill vertical OTBs are being installed behind Siemens SGT5-9000HL gas turbines.

Our highly skilled teams in Europe and in North America (Erie, PA) are experts in the design of OTBs, allowing to answer to the needs of our time while helping our customers achieve their operational goals, improve their plant efficiency, and contribute to a more sustainable future!