METEC + ESTAD 2015: CMI focuses on the future through innovation and enhanced client satisfaction

May 20th 2015

At the not-to-be-missed rendez-vous of the year for the global steel industry, CMI Industry is presenting its latest technologies and innovations aiming at increasing efficiency and eco-friendlyness of its customers production facilities.

As an international industry gathering every four years, METEC is the exhibition event for the metallurgical technology of tomorrow. METEC consistently focuses upon reflecting on current & future challenges related to modern steel production. The best technology experts in the world are meeting to exchange ideas and experience.

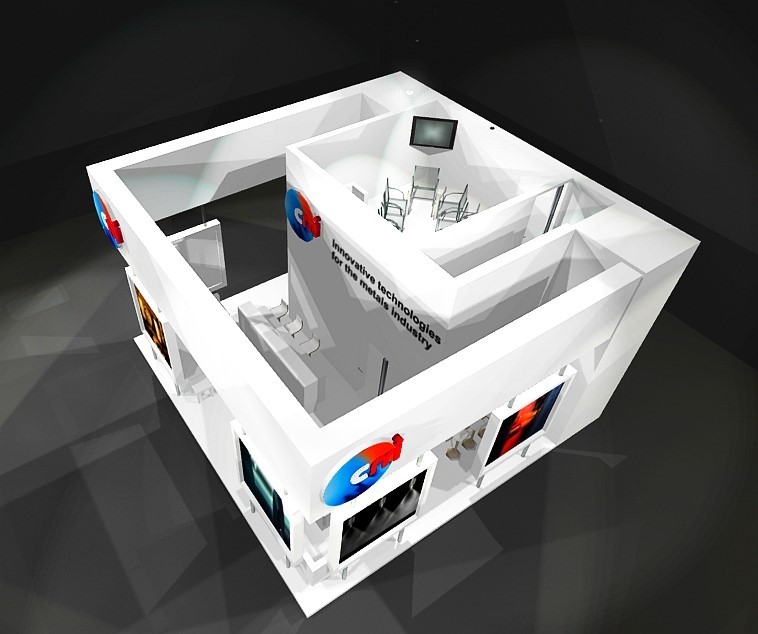

While the METEC organization expects a record attendance this year, CMI is preparing for an intense & priviliedged exchange with its clients. Planned are several tailor-made “Innovation and Technology (product & process) Workshops”, hosted directly at the CMI stand in Hall 5/ 5D04, as well as the launch of several new innovative products and high-value-added services.

One of them being CMI’s Operation & Process Expert System (OPExS™) aiming at technical assistance and guidance in the heart of our customers CGL production process. The OPExS™ is including a new integrated software analyzing all process and coil data to determine process and quality conditions and providing operational advice and guidance.

Another innovative technology introduced at this year’s METEC, is CMI’s new strip pickling process based on spray modules, to drastically increase pickling efficiency, hence increase process speed and reduce line length requirements. This technology represents a breakthrough when compared with conventional turbulence pickling. Coupled with SILASS™, CMI’s innovative high frequency magnetic field technology for Si removal destined to the pickling of silicon and high-strength steel grades, CMI offers the ideal package solution for modern AHSS and UHSS pickling lines.

ESTAD 2015 – The power of innovation

ESTAD the leading European technical conference for the steel industry, is organized by the Steel Institute VDEh in cooperation with the Austrian Society for Metallurgy and Materials, Fédération Française de l’Acier, Jernkontoret and Associazione Italiana di Metallurgia. The 2015 event takes place for the second time following the first ESTAD, Paris, 2014.

CMI is presenting 3 of their innovations at this years conference, all of which are covering the central topic of the industry: “how to improve the efficiency of lines and equipment”

New tools to detect even slight drifts on continuous processing lines (Thursday, 18 June 2015, 9:00-11:00 | Track N | Session 9)

New CMI mathematical model to cover any configuration of cold rolling operation (Thursday, 18 June 2015, 11:20-13:00 | Track L | Session 21)

CMI technology to reach efficiently best quality on reheat furnaces (Tuesday, 16 June 2015, 14:00-15:20 | Track K | Session 2)