Innovation and performance for the renovation of electrochlorination facilities at the Penly and Gravelines nuclear power plants

October 24th 2025

In recent years, EDF has entrusted John Cockerill with the renovation of the electrochlorination facilities (CTE) at the Penly and Gravelines nuclear power plants.

The seawater needed to cool the circuits of the coastal reactors is taken from there. After safety filtering, this water undergoes E-ChloPure® electrochlorination treatment, which transforms seawater into ‘bleach’ in order to eliminate biological fouling and microbial growth, thereby preventing clogging/obstruction of the exchanger tubes.

Fanny Vivenot, Chief Project Engineer, explains: “This process for producing sodium hypochlorite by E-ChloPure® electrolysis, developed in-house at John Cockerill, is a proven, economical and environmentally friendly solution. Our technology offers numerous benefits and improves the efficiency of production units.”

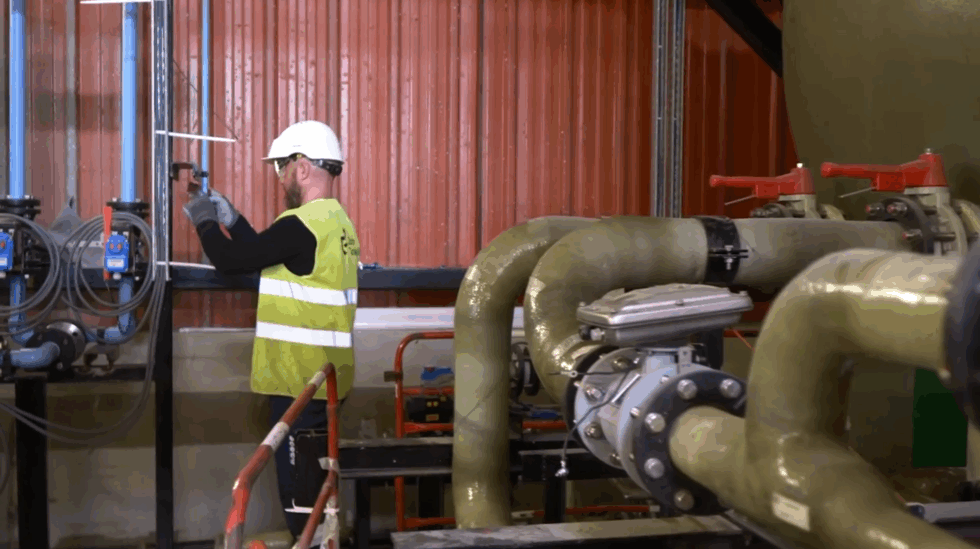

The teams at John Cockerill Nuclear Services, in partnership with John Cockerill Proserpol, implemented this technology in eight units, including two at the Penly nuclear power plant and six at the Gravelines nuclear power plant.

Prior to installing the system, an analysis of the building is mandatory in order to identify the anchorage areas where the structure can be installed. During the assembly work on Unit 5 at Gravelines, the teams shared their expertise with EDF on how to use this ferroscan.

Fanny adds: “Following the implementation of a new CTE installation, EDF agents undergo theoretical training, but the ideal is always to be able to put this theory into practice. To this end, we agreed to integrate an EDF agent, who had previously undergone training, into our teams so that he could develop his skills and use his new knowledge in the field. It’s a win-win partnership between the John Cockerill and EDF teams, who are working together to improve energy production equipment. To date, the turnkey CTE installations have been commissioned on units 1 and 3, and our customer is very satisfied with the yields generated. The CTE installations on units 2, 4 and 5 are currently being tested, and we will be able to commission them next spring. I would like to thank the whole team for their commitment and congratulate them on this success!”