Designing a HRSG that utilizes oxygen-enriched air in the combustion process instead of conventional air

October 18th 2024

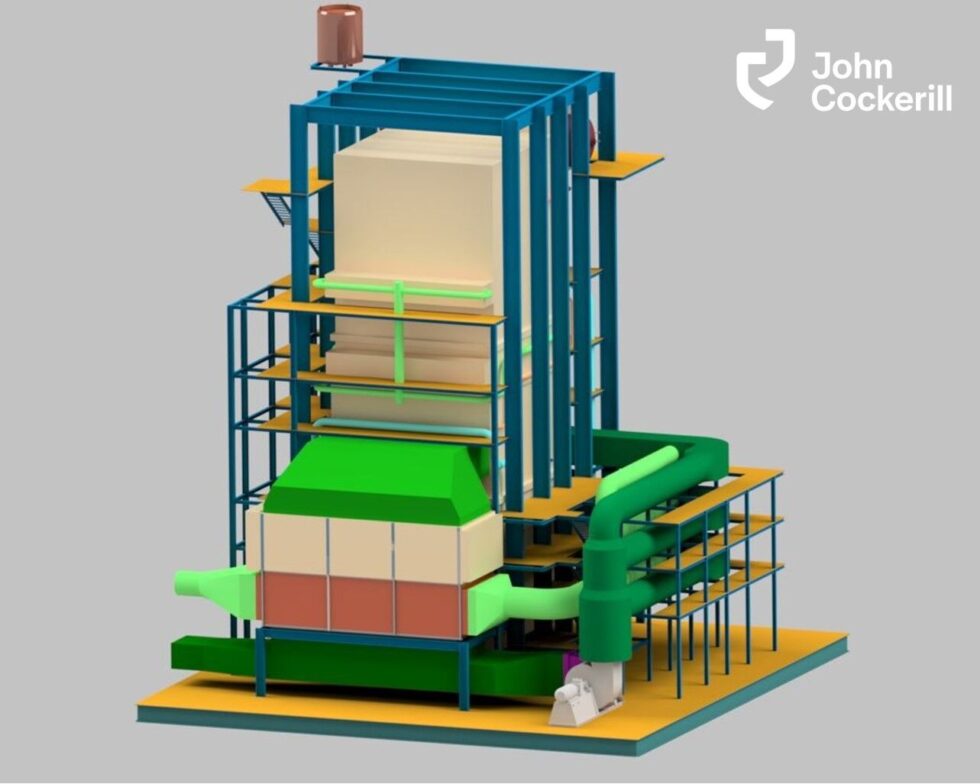

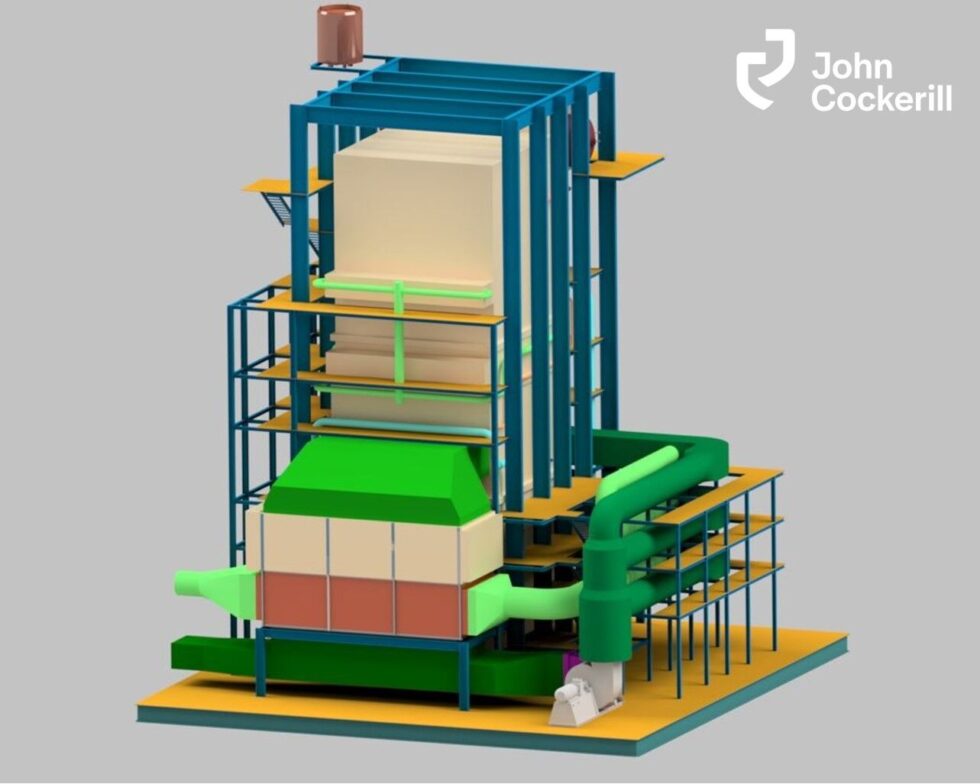

In a collaborative partnership aimed at evaluating decarbonization solutions for cogeneration facilities, TotalEnergies and Technip Energies have entrusted John Cockerill with a feasibility study to design a heat recovery steam generator (HRSG) that utilizes oxygen-enriched air in the combustion process instead of conventional air. The objective is to transform this facility into a low-carbon electricity and heat production plant by integrating an oxy-combustion HRSG with a CO2 purification, transportation, and storage system.

John Cockerill has developed a modular HRSG compatible with oxygen combustion and with a steam production capacity of 490 tons per hour. The concepts consists in extracting oxygen from the air to fuel the combustion process. By significantly reducing the nitrogen content in the combustion air, the system minimizes smoke emissions and the production of nitrogen oxides.

Moreover, the incorporation of a CO2 capture unit enables an impressive reduction of over 85% in CO2 emissions released into the atmosphere, thus mitigating the environmental impact of the installation on global warming and air quality.

This groundbreaking study will be presented by TotalEnergies and Technip Energies on October 22nd at the Greenhouse Gas Control Technology Conference (GHGT-17) in Calgary, Canada.

For our Group, the potential for future perspectives is vast and promising, particularly with the goal of achieving zero-carbon objectives. Upcoming developments will enable the production of green electricity through our innovative designs of recovery boilers tailored for alternative fuels, such as hydrogen and biofuels.

At John Cockerill, we are committed to addressing the needs of our time and supporting our clients in their journey toward sustainable production.