CMI to supply two acid regeneration plants for Shandong Iron & Steel Group, China

February 03rd 2017

In the framework of the construction of its new flat steel complex in the Shandong province on the Chinese east coast, Shandong Luzhong Steel Logistics Co.Ltd., a subsidiary of Shandong Iron and Steel Group, ordered two acid regeneration plants (ARPs) from CMI Industry.

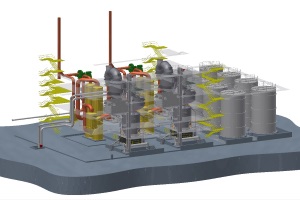

While the customer’s new complex produces almost five million tons of hot strip and two million tons of surface-finished cold strip per year, the twin ARP installation to be provided by CMI, will recover 17.000 liters per hour of waste acid. Both ARPs are based on CMI’s state-of-the art fluidized bed (FB) technology, providing operator friendliness, as well as a small footprint and easy oxide handling, all of which are factors based on which Shandong Iron & Steel Group, one of China’s top ten steel producers, opted for the FB technology.

One of the highlights of the acid regeneration process is the environmentally friendly design of the twin installation. As such, the highly efficient CMI plants allow for a close to 100% recycling of the spent hydrochloric acid coming from the pickling process.

The purified hydrochloric acid is then led back into the customer’s hot-rolled steel strip manufacturing process. This not only reduces the environmental footprint of the steel complex but also its operating cost.

Additionally, the new ARP´s are equipped with CMI’s newly developed heat recovery system that allows gas savings of up to 6%, as well as with CMI’s latest technology to reduce plume formation at the stack.

Decisive factors for choosing CMI for this project were the company’s extensive experience in designing and building fluidized bed acid regeneration systems, but also the high process security of the plant concept, providing highest throughput and plant availability.

The twin ARP facility is scheduled to start operation in June 2017.