The downstream phase of metals production is undergoing rapid transformation as requirements for surface cleanliness, dimensional accuracy, mechanical properties, and the processing of new-generation grades including AHSS, UHSS, electrical steels, and advanced aluminium alloys continue to intensify. To address these challenges, we develop and integrate technologies engineered for process stability, energy efficiency, emissions reduction, and high line availability.

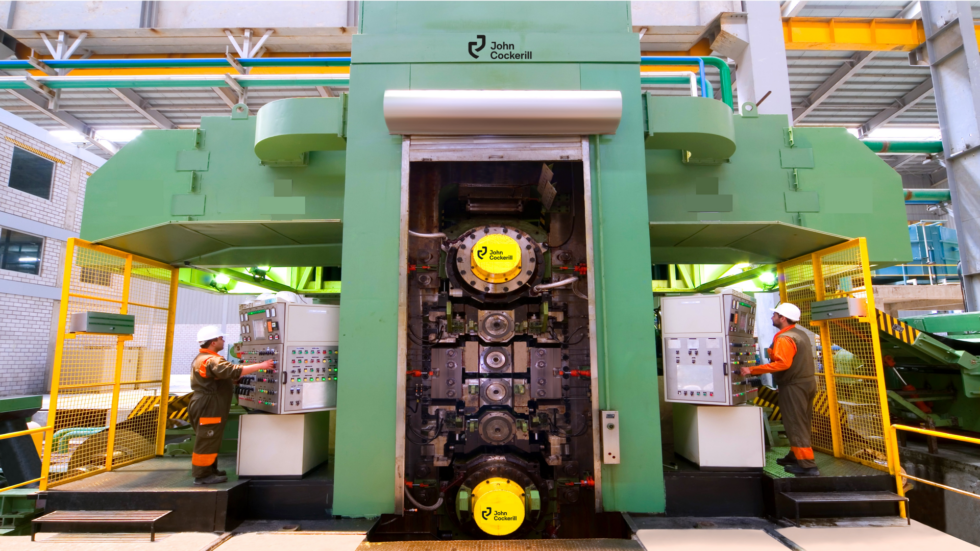

Our expertise spans the full spectrum of strip-processing and rolling operations, combining metallurgical know-how, automation, and robust line design to ensure consistent production of high-quality strip across wide operational ranges. We engineer systems to optimise strip behaviour, thermal cycles, tension control, roll-force dynamics, and surface-conditioning parameters, ensuring reliable performance even under demanding product mixes.

Our downstream offering covers the full spectrum of processing and rolling solutions including pickling, acid regeneration, cold rolling, strip processing, and finishing lines.

To further elevate production performance, we integrate several of John Cockerill’s innovative technologies across our lines:

- E-Si® Electrical Steel Technology: Complete GO and NGO electrical steel production solutions capable of processing down to 0.15 mm thickness, incorporating high-precision annealing, pickling, and coating systems that ensure outstanding magnetic efficiency.

- Jet Vapor Deposition (JVD®): A state-of-the-art vacuum zinc-vaporisation technology achieving ~99.5% zinc yield with extremely uniform coatings—ideal for automotive, appliance, and high-end corrosion-resistant applications.

- Eagle Eye Coating™: An advanced air-knife and bath-control system that ensures real-time coating visibility, superior thickness uniformity, reduced zinc consumption, and lower energy demand.

- Blowstab® HSS Cooling: Patented ultra-fast cooling technology delivering rates up to 500 °C/s, enabling the production of next-generation AHSS with minimal oxidation and excellent metallurgical consistency.

- Ultra Dry Cooling (UDC®) & IWAC®: Flexible dry and wet cooling modules providing precise thermal control, higher strip-quality stability, and improved energy efficiency across diverse product mixes.

We support an extensive range of materials such as carbon steels, stainless steels, silicon steels, aluminium, and other non-ferrous metals enabling steel makers to expand product portfolios while maintaining stringent quality standards.

By combining process engineering expertise with innovative proprietary technologies, we offer a downstream platform that delivers measurable improvements in productivity, product quality, energy consumption, and total lifecycle cost.